This website uses cookies to ensure a better user experience.

To get more information, please read our Cookie Statement.

Strain transfer across grain boundaries in MoS2 monolayers grown by chemical vapor deposition

Together with our colleagues Valentin Jadriško, Borna Radatović, Davor Čapeta, and Marko Kralj, a group of researchers from Universität Münster, Germany, has recently published a paper on the transfer of strain at the grain boundaries of MoS2 monolayers grown by chemical vapor deposition. The results demonstrate that large-area artificially grown MoS2 monolayers are promising for mass-produced nanomechanical devices.

Strain transfer across grain boundaries in MoS2 monolayers grown by chemical vapor deposition

Iris Niehues, Anna Blob, Torsten Stiehm, Robert Schmidt, Valentino Jadriško, Borna Radatović, Davor Čapeta, Marko Kralj, Steffen Michaelis de Vasconcellos, Rudolf Bratschitsch

2D Materials 5, 031003 (2018).

Monolayers of transition metal dichalcogenides (TMDC) mechanically exfoliated from bulk crystals have exceptional mechanical and optical properties. They are extremely flexible, sustaining mechanical strain of about 10% without breaking. Their optical properties dramatically change with applied strain. However, the fabrication of a large number of mechanical devices is tedious due to the micromechanical exfoliation process.

Alternatively, monolayers can be grown by chemical vapor deposition (CVD) on the wafer scale, with the drawback of cracks and grain boundaries in the material. Therefore, it is important to investigate the mechanical properties of CVD-grown material and its potential as a material for mass production of nanomechanical devices.

In this work optical absorption of CVD-grown MoS2 monolayers was examined with applied uniaxial tensile strain. We derive a strain-dependent shift for the A exciton of −42 meV/%. This value is identical to MoS2 monolayers, which are mechanically exfoliated from natural molybdenite crystals. Using angle-resolved second-harmonic generation spectroscopy, we find that the applied uniaxial tensile strain is fully transferred across grain boundaries of the CVD-grown monolayer. This work demonstrates that large-area artificially grown MoS2 monolayers are promising for mass-produced nanomechanical devices.

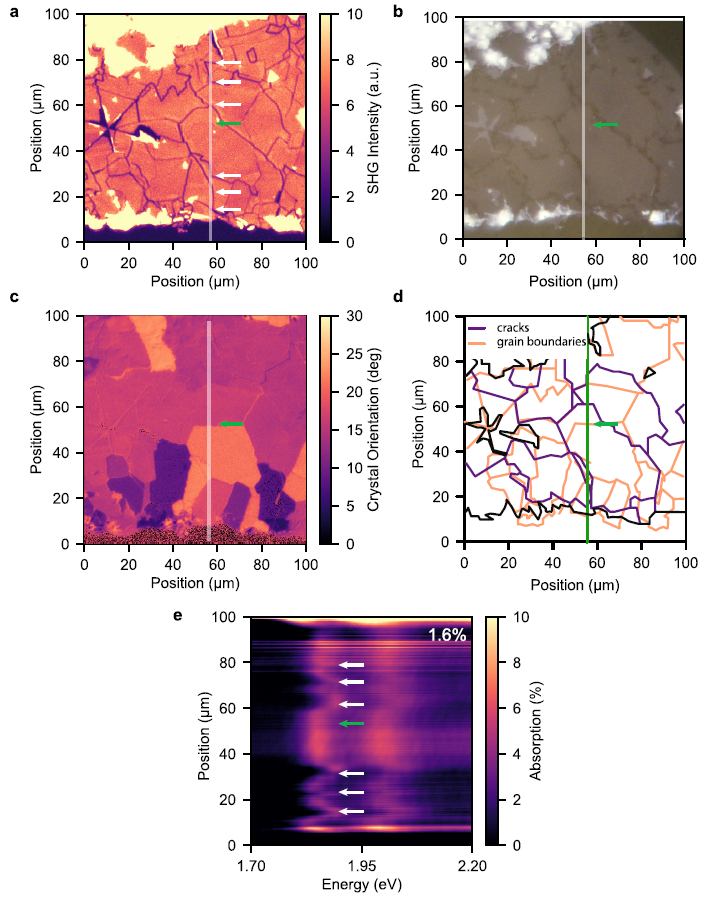

Cracks and grain boundaries in the CVD-grown MoS2 monolayer. (a) SHG intensity map of the investigated area (color-coded). Multiple cracks and grain boundaries are visible as purple lines (no/less SHG intensity). Few-layer areas in the upper and lower part of the image have a high SHG intensity (yellow). The MoS2 monolayer area exhibits a homogeneous SHG intensity. The vertical white line indicates where the spatially resolved absorption spectra are recorded. Cracks in the monolayer along this line are marked with white arrows. (b) White-light reflection image of the sample after the strain measurement. Cracks are visible as dark lines. (c) Angle-resolved SHG intensity with domain orientations (color-coded) and grain boundaries. One prominent grain boundary is marked with a green arrow. (d) Positions of cracks (purple lines) extracted from the reflection image in (b) and grain boundaries (orange lines) from the angle-resolved SHG image in (c). Black lines indicate few-layer areas. (e) Strain transfer map recorded at 1.6% strain during the second straining cycle. The white arrows indicate where no strain is transferred to the monolayer. The green arrow marks the position of the prominent grain boundary in (a) and (b), where strain is fully transferred.